Quality Control

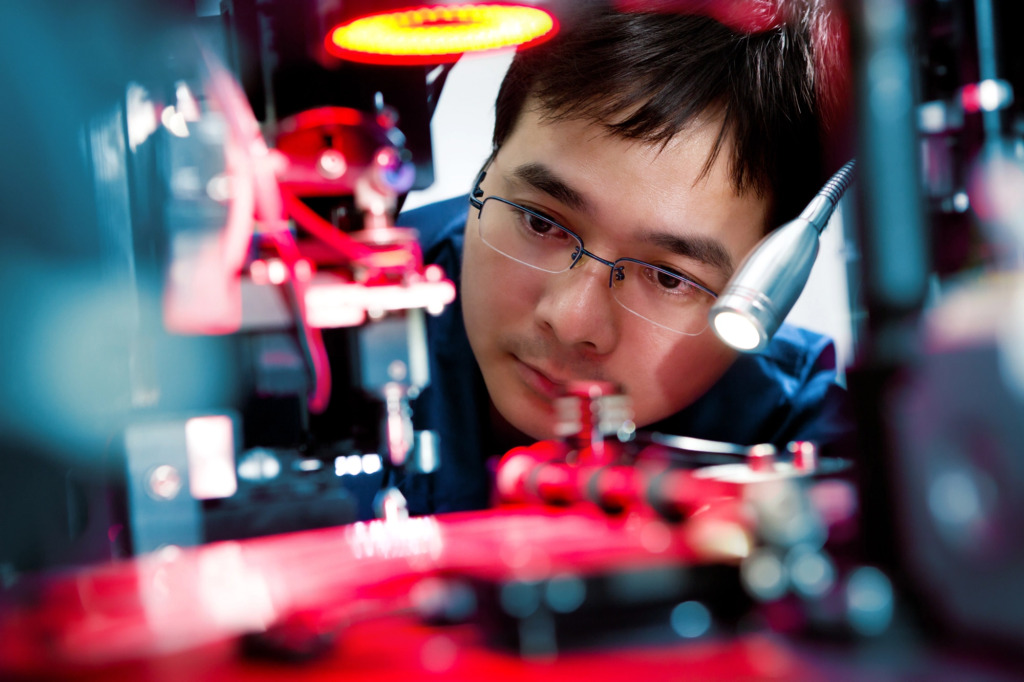

Take the Headache Out of China Quality Control

Managing quality control in a factory in China takes extensive effort, but many businesses learn the hard way what happens when quality control is ignored. Product defects can run rampant (even if the sample quality was acceptable), and many businesses aren’t aware of product issues until after bulk shipments have been made to local warehouses. Hifida specializes in quality control management in China factories, and we have the time, resources, and expertise to do it right. Our team will be onsite, personally supervising quality control procedures at your supplier’s factory, which allows us to guarantee product quality.

China Quality Control: Hifida’s Step-by-Step Process

Initial Inspection of Quality Control Processes

Hifida takes in the whole picture of what quality control processes may already be in place at your chosen factory. If appropriate quality control is already present, our experts will supervise production to ensure that those procedures are followed. If quality control is lacking, Hifida will develop quality control processes, catered to your product, and will implement them with the supplier.

Analyzing Manufacturing Risk for Determination of Acceptance

Hifida leverages its quality control expertise to identify manufacturing risk and to limit quality issues. This includes implementing avoidance strategies, risk transfer, mitigation techniques to determine what baseline acceptance is for production.

Supervising Production

Once we have invoicing data, and once we’ve created a streamlined plan with your suppliers, Hifida works with you to develop exceptionally accurate, long-term order forecasting predictions. Our team will consult with you on what to purchase and when to purchase it to make sure you are fully stocked for your busy shopping season.

Final Product Inspection

While Hifida performs regular quality control tests on products as they’re made, our team will conduct a final product inspection after manufacturing is complete. This allows us to double-check for any product defects, packaging issues, or any other problems that would affect product quality.

Approval to Ship Product

Hifida gives the final approval for products to be shipped, whether their being shipped via sea freight, or moving to a China fulfillment warehouse for direct-to-customer shipping.

Hifida’s Quality Control Fees

Hifida’s quality control fees are hourly based, and clients can choose how much, or how little, of our services they need. Your business may only need a small scope of our quality control expertise, or you may want the entire suite of services that Hifida offers. Our pricing is catered to how much of our services you need.

Tell us what specific services you need, and Hifida will do it. It’s as simple as that.

Need Help Importing From China?

Click below to get in touch with a Hifida Expert

quality control FAQ

What are the most common mistakes in China quality control?

What are the most common mistakes in China quality control?

While there’s multiple mistakes that can be made when considering quality control in China, we have found that the most common are:

- Not properly evaluating the credibility of suppliers

- Not performing onsite inspections of China suppliers

Properly evaluating the credibility of suppliers can help to avoid factories that will be problematic with quality control processes, and onsite inspections can help you avoid trade companies, as well as ensure quality control processes are in place and consistently followed.

How much should you pay for quality control in China?

How much should you pay for quality control in China?

The price range for quality control will range widely. It will largely depend on the company you chose to provide services, as well as the specific services you need performed.

Why is quality control better in America than China?

Why is quality control better in America than China?

This is actually a misnomer. Quality control isn’t better in America, it’s just that it’s harder to make sure quality control processes are followed in China. The common reasons for this include:

- Language barriers (many high-quality factories in China don’t have staff that can speak English)

- Supervision difficulty (it’s far more difficult to travel to China and supervise production than it is to do the same at a local factory)

The manufacturing industry in China is extremely robust, and there are many factories that are capable of understanding, and following, strict quality control processes. Many companies rely on third-party expertise to help supervise quality control in a China factory (like relying on the services of a sourcing specialist, like Hifida)

How can I avoid quality problems during the manufacturing process?

How can I avoid quality problems during the manufacturing process?

There are multiple strategies you can use to avoid quality problems during the manufacturing process:

- Provide clear expectations for quality control procedures to manufacturers

- Supervise production to ensure that quality control processes are followed

- Respond quickly to production issues as they arise

What should my business do if we find product defects?

What should my business do if we find product defects?

It depends on when you find product defects. If you only notice product defects when the bulk order has been delivered to its final destination, it’s largely too late to take meaningful action. You can attempt to send the products back and get a refund, but that still won’t give you the time you lost back, and it will still tie up capital while you renegotiate with a supplier.

If you find product defects during production (which may happen, especially if quality control processes are being closely followed), you should:

- Determine what is causing the defect

- Make production changes or material changes as needed

- Work closely with your China factory to ensure the problem has been resolved

How can I make sure that my products meet my quality expectations?

How can I make sure that my products meet my quality expectations?

The best way to make sure that products meet your quality expectations is to:

- Set clear expectations of what your quality expectations are before production

- Supervise quality control onsite

- Respond quickly as production issues arise

- Perform a final inspection before products are shipped

What are the challenges to maintaining quality control in a China factory?

What are the challenges to maintaining quality control in a China factory?

While the manufacturing industry in China is well-developed, there are some unique challenges to maintaining quality control in a China factory. Some of those challenges are:

- Language barriers

- Improper or unclear expectations of quality

- Inability to react quickly to production issues (unless you’re physically present)

- Inability to ensure quality control processes are followed by not being onsite during production

How do I choose a high-quality factory in China?

How do I choose a high-quality factory in China?

Choosing a china supplier is challenging, but it’s worth the effort. This is especially true since choosing a high-quality factory will reduce the likelihood (but not eliminate) of issues with quality control. Here are some tips to follow in order to choose a high-quality factory in China:

- Research multiple options that may fit your needs

- Filter choices based on their experience, product specialty, lead times, and communication skills

- Always perform a thorough sampling process

- Allow as much time as needed to follow these tips without feeling rushed

If you think that your business doesn’t have the time, resources, or expertise to find a factory in China that’s a good fit, you may want to look to the services of a sourcing specialist, like Hifida.

Can I trust my supplier to conduct quality control in China?

Can I trust my supplier to conduct quality control in China?

This is a mixed answer. Your supplier should absolutely participate in your quality control strategy, but they should not be left to be solely responsible for following it. Whether quality control processes are followed is ultimately up to you, so you can’t afford to leave it entirely up to your supplier to handle.